Motor energy dissipation performance is mainly in the following aspects:

1.The motor load rate is low.

Due to the improper selection of motor, the rich amount of or changes in production technology, will make the motor actual work load far less than rated load, accounted for about mounted units with a capacity of 30% to 40% of the motor running in 30% to 50% of the rated load, the operating efficiency is too low.

2. the power supply voltage is too low or too low voltage.

Because of the unbalance of three-phase four wire low voltage power supply system single-phase load, the motor, the asymmetrical three phase voltage, electric motors produce negative torque, the three-phase voltage asymmetry increases, electric motors produce negative torque and increase the loss during the operation of the machine. In addition, the power grid voltage is too low for a long time, so that the normal operation of the motor current is too large, so the loss increases, the three-phase voltage asymmetry is bigger, the voltage is lower, the loss is bigger.

3.old (obsolete) type of motor is still in use.

These motors use E grade insulation, large size, poor starting performance, low efficiency. Although the transformation, but there are still many places in the use of.

4. poor maintenance management.

Some units of the motor and equipment are not in accordance with the requirements of maintenance, long-term operation of the motor, so that the loss is increasing.

In view of these energy performance, the choice of what kind of energy saving program is worth studying.

1. Choice of energy-saving motor.

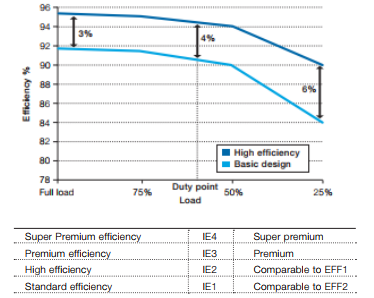

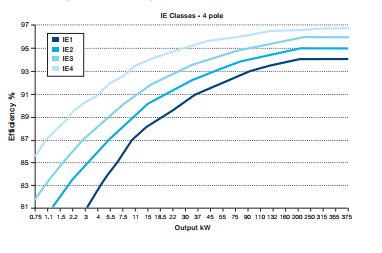

Compared to the high efficiency motors and general motors, to optimize the overall design, choose the high quality copper windings and silicon steel sheet, reduce the power loss, the loss of 20% to 30%, improve the efficiency of 2% ~ 7% and the investment recovery period is generally 1 to 2 years, for a few months. By comparison, the efficiency of the motor is improved by 0.413% compared with the J02 series motor. Therefore, it is imperative to replace the old motor with high efficiency motor.

2.the appropriate choice of motor capacity to achieve energy saving.

State of the three-phase asynchronous motor 3 operating areas were as follows: load rate in the 70%~100% for the economic zone between the load rate of 40%~70% for the general operating area of the load rate of 40% in the following non economic zone. Improper selection of motor capacity will undoubtedly cause the waste of electrical energy. Therefore, it can reduce the power loss and save the power consumption by adopting the appropriate motor to improve the power factor and the load rate.

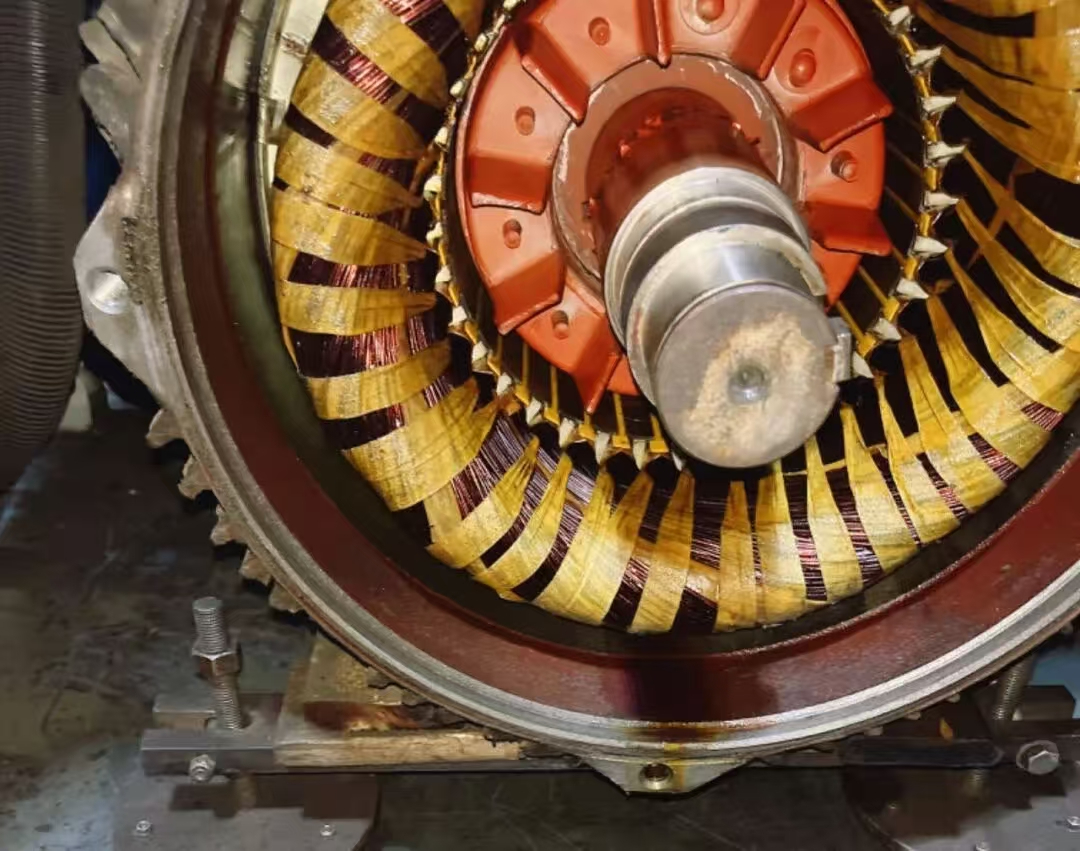

3. using magnetic slot wedge instead of the original slot wedge.

Asynchronous motor in no-load iron loss is reduced by magnetic slot wedge, no-load additional iron loss is caused by slot effect in the motor harmonic magnetic flux is generated in the stator and rotor core. The stator and rotor in the core sense of the consumption of additional iron loss high frequency called pulsation loss. Also stator and rotor tooth sometimes positive and sometimes staggered, tooth surface gear cluster flux changes, in the line of tooth surface layer eddy current, loss of surface. Pulsating loss and surface loss, collectively referred to as the additional high frequency loss, which accounted for 70% to 90% of the stray loss of the motor, the addition of 10% ~ 30% said to load additional loss is generated by the leakage magnetic flux. Although the use of magnetic slot wedge will make the starting torque is decreased by 10% to 20%, but the magnetic slot wedge motor than the ordinary Slot Wedge motor iron loss can reduce the 60K and are so well adapted no-load or light load start motor transformation.

4. using an automatic conversion device of Y/ delta.

For the equipment to solve the light load of electric energy waste phenomenon, under the premise of the non replacement of the motor can be automatic switching device to achieve energy saving objective using Y /]. Because of the three-phase alternating current, the voltage obtained by the different methods of the load is different, so the energy absorbed from the power grid is also different.

5.the motor power factor reactive power compensation.

To improve the power factor and reduce the power loss is the main purpose of reactive power compensation. Power factor is equal to the active power and apparent power. Usually, the power factor is low, resulting in the current is too large, for a given load, when the supply voltage is certain, power factor is low, current, the greater the. So the power factor is as high as possible to save energy.

6. winding motor liquid speed.

The liquid resistance speed regulation technology is developed on the basis of the traditional product liquid resistance starter. The purpose of stepless speed regulation is to change the size of the gap between the plate and the resistance. It also has good starting performance it electrified for a long term, bring the heating problems, due to the unique structure and reasonable heat exchange system, its working temperature is defined under the proper temperature. Winding motor with liquid resistance speed control technology, to the work reliable, installation convenient and save energy by a big margin, easy maintenance and low investment and the rapid promotion, for some of the speed control accuracy is not high, speed range requirements is not wide, and less frequent speed winding type electric motive, wind machine, pumps and other equipment of large and medium-sized wound type asynchronous motor using a liquid control effect is remarkable.