Selection Voltage for motor 101: Why and How to Choose the Right Voltage for Your Motor

Consider cabling, size, installation specifics, windings as well as operational environment for make the right choice.

Choosing the right motor can save the user time, space and money. Here are some things to consider when choosing between a low voltage motor and a medium voltage motor.

Low-voltage motors are a preferred choice for motors of 400kw and below. Furthermore, in special VFD (variable frequency drive) applications, low-voltage motors can go up to over 400kw. However, with the increase in horsepower (hp), there will be some advantages to changing to a medium-voltage motor.

Cabling

In low voltage motors, as the hp range increases, the cable size increases to handle the increase in amps. This adds the cable costs, especially during longer cable runs in large facilities or remote pumping stations. This increase in diameter also allows for a larger turning radius, which makes it more difficult to make connections inside the terminal box. This can be time-consuming and poses additional risk for maintenance personnel during the initial setup of the motor.

The lower current in a medium voltage motor allows for smaller cables (leads), even at higher horsepower. The use of smaller size leads reduces the cost per foot of a long-distance connection to a remote pumping station. In addition, in the process of motor connection, small size wire is easier to use in the terminal box and connection. This reduces the time it takes maintenance personnel to make connections and reduces the risk of damaging cables. The higher costs of medium-voltage equipment are easily offset in longer distribution cable applications.

Size & Installation Specifics

When considering space and installation details on site, the motor size should be considered as a choice between a low-voltage or a medium-voltage motor that has an impact on the components in the overall system.

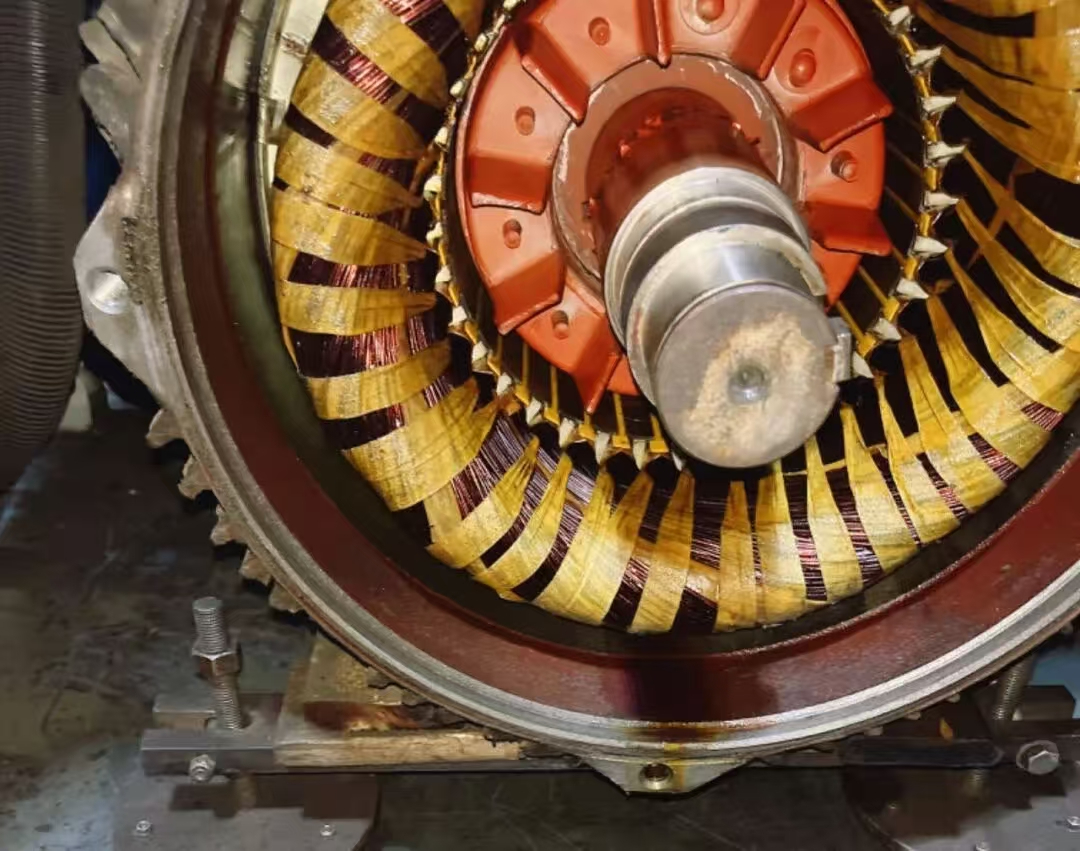

Winding

Each coil of the medium voltage motor must go through the external insulation wrapping test and insulation treatment process.

This is a labor-intensive process but is well suited to the rigor of voltage shocks in medium-voltage systems. In addition, because the conductors used in the windings are smaller, it is possible to have more turns and thus greater flexibility in electrical design, making it possible to achieve specific performance characteristics.

Operational Environment

The operating environment of the motor, the ambient temperature, altitude, and the choice of cooling method, cost and other factors are all taken into consideration.

There is no simple answer to choosing a low or medium voltage motor as the pump system or other application, if you have any questions, please feel free to contact our engineers. sunny(at)doulipower.com